Street Sweepers

Boston Gear

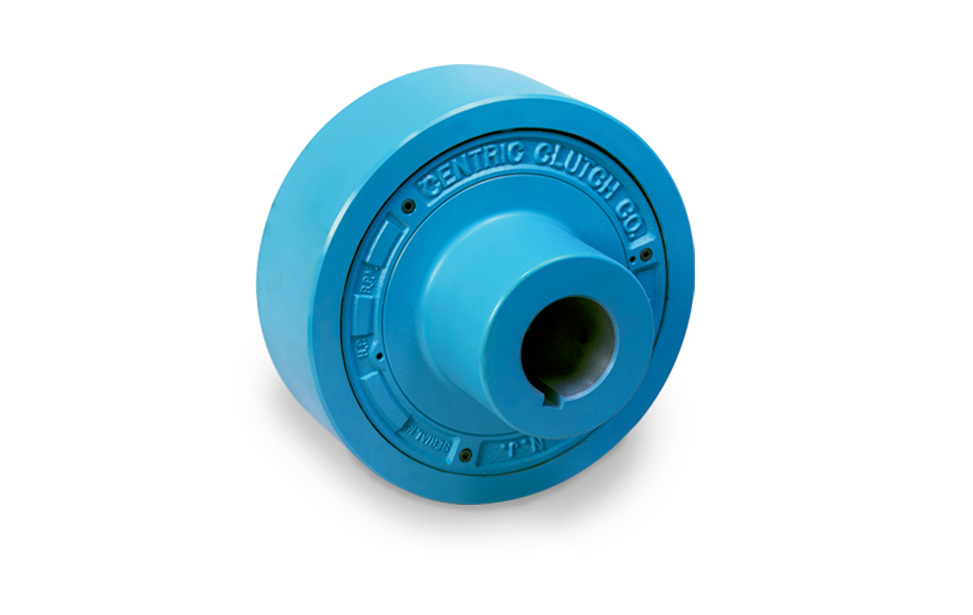

Centric Centrifugal Clutch

Centrifugal clutches were originally used as soft start clutches and are often used on high inertia type applications. The starting torque required for heavy equipment can cause torque spikes that shorten the life of motors, speed reducers and other drive train components. Spring loaded centrifugal clutches can be designed to engage at a specific RPM offering a warm-up period for engines and turbines. These clutches are often used on back-up generators or “stand by” type systems because time has no effect. Centrifugal clutches are a time tested method of starting heavy rotating equipment with ease.

Spring controlled centrifugal clutches can be used to brake/slow down a runaway system. Applications like elevators or lift systems need to have a back-up fail safe mechanism. The clutch can be designed to engage at a specific RPM and slow the decent of the load. A lift system manufacture has recently redesigned their product to incorporate a centrifugal clutch thus reducing safety concerns.

All of these clutches are custom fit to the application and offer unmatched design flexibility.

Features

- Self-actuating/automatic clutch that requires no external controls

- Highly efficient with no energy loss at rated speeds

- Provides soft start acceleration

- Spring loaded design offers controlled engagement at a specific RPM

- Allows for smaller motors to run more efficiently at start-up

- Provides shock protection for equipment that could be jammed or overloaded

- All clutches are custom designed to engage per the customer requirements

- Vertical lift-out and QD bushing designs available upon request

- Custom centrifugal clutches can be designed to be RPM limiters or brakes on runaway systems