HiflexDRIVE - Aseptic

The combination of the BK17 range and permanent magnet synchronous motors (PMSM) means not only that the PMSM design is superior at converting electrical energy into mechanical power, it also offers the added benefit of maintaining constant speed independent of the load. This means that motor speed does not vary - despite overload variations or cases of voltage drop - as long as the mains frequency is kept constant. PMS motors are perfectly suitable as drives for applications with constant torque such as conveyor systems.

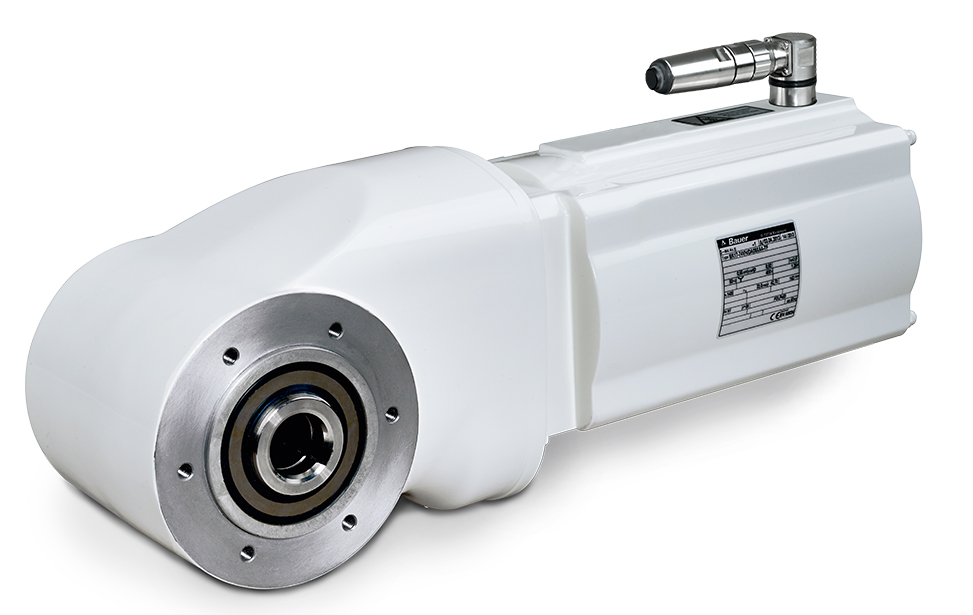

HiflexDRIVE in Aseptic Design

Aseptic drives are carefully designed for applications where regular washdowns are required to maintain a clean environment. The motor is designed so that a fan and cooling ribs are not required, thereby allowing for a completely smooth outer casing with a non-drive end which is sealed. This eliminates any dirt traps on the motor casing and also prevents re-infection of the local environment caused by air movement from a cooling fan.

The design also includes a very high level of ingress protection, up to IP69K; which is a special designation for washdown applications involving high pressure, high temperature water. In addition, the aseptic drive is painted using an acid and alkali resistant formula, which can withstand chemicals with a pH range of 2 – 12. As a result the new drive system can withstand the cleansing solutions and disinfectants that are commonly used without affecting its performance.

The combination of the BK17 range and permanent magnet synchronous motors (PMSM) means not only that the PMSM design is superior at converting electrical energy into mechanical power, it also offers the added benefit of maintaining constant speed independent of the load. This means that motor speed does not vary - despite overload variations or cases of voltage drop - as long as the mains frequency is kept constant. PMS motors are perfectly suitable as drives for applications with constant torque such as conveyor systems.

Features

- Torque: 80 up to 330 Nm

- Ratio 4,54 ... 108,6 :1

- Low weight

- Easy handling and space saving installation

- Cost reduction in the plant dimensioning

- High efficiency through 2 stage gear design

- Low pass-over height

- Reduced cleaning times through smooth water repellent surfaces

- Special coatings

- Gear oil and shaft seals suitable for use together with foodstuffs

- CE-Mark

- CSA, UL, ATEX, GOST, CCC, ISO9001, ISO14001, OHSAS18001

- Motors according to EN 60034

- Efficiency Classes IE1 to IE4

- Drives optimised for partial load condition acc. to EN 50598-2

- PSM Technology with over 30% energy saving under partial load

- Scalable motor technologies for worldwide operation

Innovative Geared Motor Technologies

Trend-Setting Motor Technologies

Eberhard-Bauer-Str. 37

73734 Esslingen - Germany